A frozen valve in the lower stage rocket booster of SpaceX delays its debut flight. Valve freeze in pressure-fed engines can have several causes, including:

- Contamination: If foreign objects, such as dirt or debris, get into the fuel or oxidizer, they can block the valve, preventing it from opening and closing properly.

- Corrosion: Over time, the valve’s internal components can corrode due to exposure to harsh chemicals, such as fuel and oxidizer. This corrosion can cause the valve to freeze in place.

- Wear and tear: The constant opening and closing of the valve can cause the internal components to wear out, leading to a valve that is stuck in one position.

- Improper maintenance: If the valve is not properly maintained, it can become clogged with debris or corroded, leading to a frozen valve.

- Manufacturing defects: In rare cases, a valve may have a manufacturing defect that causes it to freeze in place.

Rocket boosters and other spacecraft use complex valve systems to distribute propellants or fluids that often have unique properties, such as being chilled down to super-cold levels. Space industry executives have said that developing valves that work just right under such conditions is often a challenge.

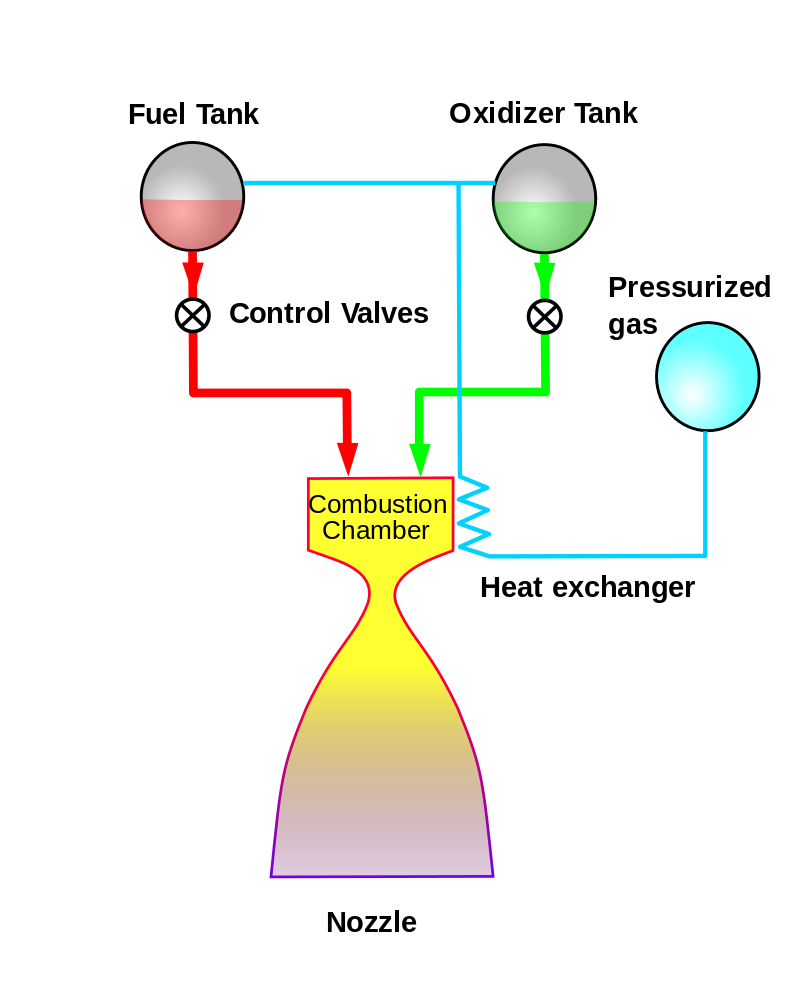

The pressure-fed engine in SpaceX is a class of rocket engine designs. A separate gas supply, usually helium, pressurizes the propellant tanks to force fuel and oxidizer to the combustion chamber. To maintain adequate flow, the tank pressures must exceed the combustion chamber pressure.

Source: https://en.wikipedia.org/wiki/Pressure-fed_engine

Pressure fed engines have simple plumbing and have no need for complex and occasionally unreliable turbopumps. A typical startup procedure begins with opening a valve, often a one-shot pyrotechnic device, to allow the pressurizing gas to flow through check valves into the propellant tanks. Then the propellant valves in the engine itself are opened. If the fuel and oxidizer are hypergolic, they burn on contact; non-hypergolic fuels require an igniter. Multiple burns can be conducted by merely opening and closing the propellant valves as needed, if the pressurization system also has activating valves. They can be operated electrically, or by gas pressure controlled by smaller electrically operated valves.