An ARC study reported that:

“The cost of performing predictive maintenance on valves can be up to five times less expensive than preventive maintenance and 10 times less expensive than corrective maintenance, even before the costs of downtime are figured in.”

And yet, these are often not monitored. With a scarcity of trained engineers, this becomes even more critical.

Maximize the value of your valves

The Valve App creates value for Maintenance, Reliability Management, and Operations. Here are five ways you can benefit from it:

- Reduce energy/product losses

- Plan investments more accurately

- Optimize maintenance planning for shutdowns

- Minimize on-site inspections

- Lower risks by getting early warnings

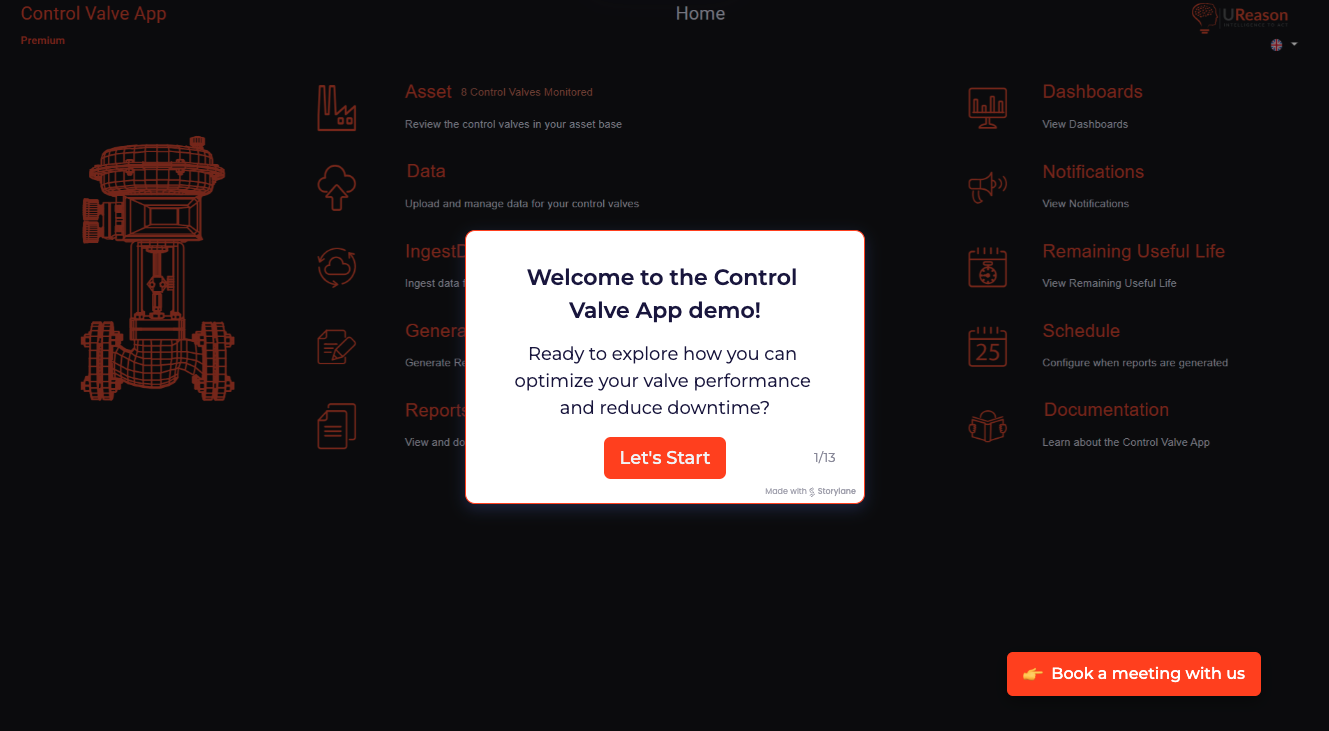

The Valve App is easy to integrate

UReason Valve App is a brand-agnostic valve monitoring solution that supports many valve brands and is easy to integrate with many data platforms and CMMS. It connects to many data sources, providing a comprehensive view of valve health and performance.

- Plug-and-play

- Supports Air/Electrical actuators

- Benchmarks valve performance

Get continuous insights into your valves in real time

Asset management perspective

- Determining asset (valve and actuator) Remaining Useful Life for better maintenance and Capital Expenditure planning.

- Real-time insights for quick response and proactive maintenance.

- An automatic connection to CMMS that creates automated work processes.

Reliability management perspective

- Detailed (graphical) insights on valve behaviour for deep understanding.

- Root-cause analysis models for dysfunctions.

- Benchmarking over the total asset base.

Operations perspective

- Additional insights for product/energy loss.

- Reduce Fugitive Emissions by addressing stiction, stick&slip and stem/packing issues