This article is part of a series published by UReason about failure modes and effect analysis of essential components that are common in various industrial processes such as control valves, pneumatic actuators, electrical actuators, motors, and centrifugal pumps.

In the previous section, some of the most common control valve failure modes (mechanisms) were described. Mapping these to an FMEA we need to:

- List components/assets and/or functions;

- Describe their potential failure mode(s);

- Describe the potential effect(s) of failure;

- Describe the potential cause(s)/failure mechanisms of failure;

- Describe the existing/current controls; and

- Describe the recommended actions.

We will, in this example, also list the consequences – a step towards FMECA.

To have a quantitative measure that helps you decide which failure mode(s) to focus on the RPN, Risk Priority Number, will be calculated using the following formula: RPN = Occurrence (O) x Severity (S) x Detection (D)

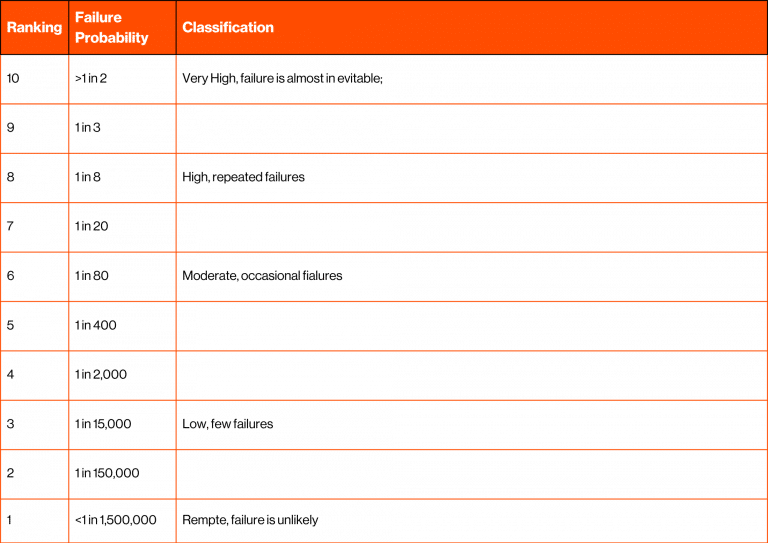

Occurrence Ranking

In the formula for RPN, Occurrence ratings are based on the likelihood that a cause may occur based on past failure and performance. Here we estimate the likelihood or frequency with which each failure mode is expected to occur on a scale from 1 to 10, with 1 being the least frequent and 10 being the most frequent. This rating should be based on historical data, experience, or engineering analysis and represents the occurrence of failure during lifetime. An example of Occurrence ranking:

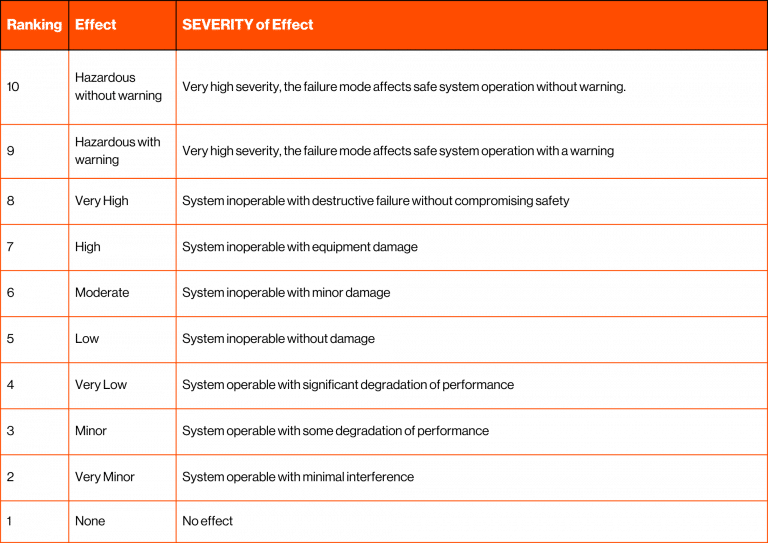

Severity Ranking

In the formula for RPN, Severity is the seriousness of the effect of potential modes. Assessing the Severity for each failure mode we will use a numerical scale typically ranging from 1 to 10, with 1 being the least severe and 10 being the most severe. This scale is somewhat subjective and should be determined by the team’s consensus based on the potential impact on safety, quality, or other critical factors. The severity rating should consider both the consequences and their potential harm. An example of Severity ranking:

Detection ranking

Detection rating estimates how well the control can detect the failure mode. To do this assess the effectiveness of current detection methods or controls in place to catch or prevent the failure mode from causing upset(s). This is also rated on a scale from 1 to 10, with 1 indicating the highest detection effectiveness (very likely to detect) and 10 indicating the lowest detection effectiveness (very unlikely to detect):

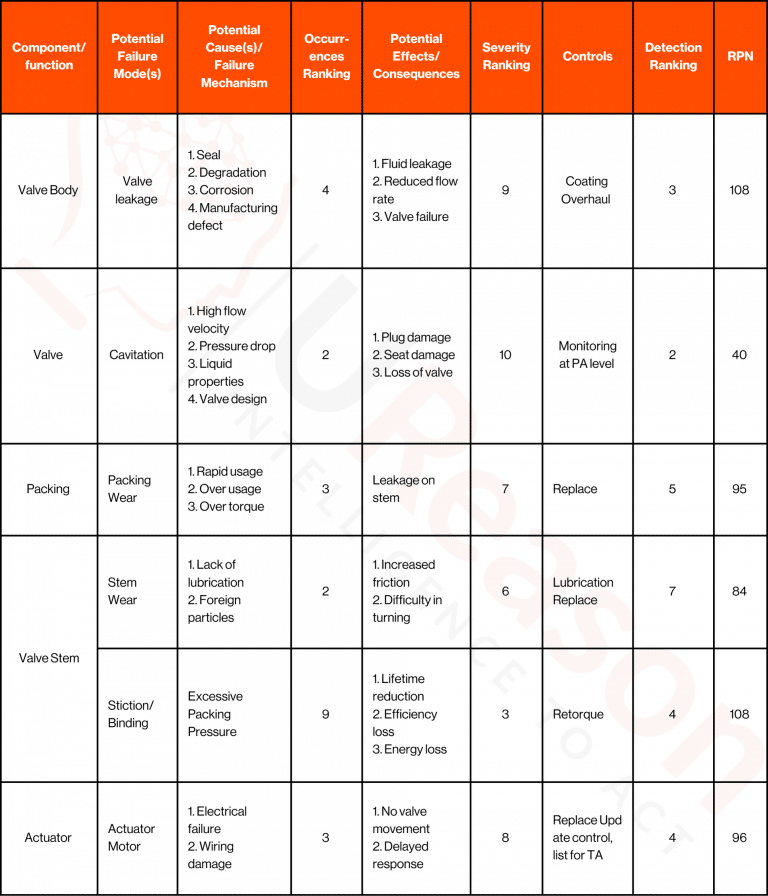

Creating the FMEA

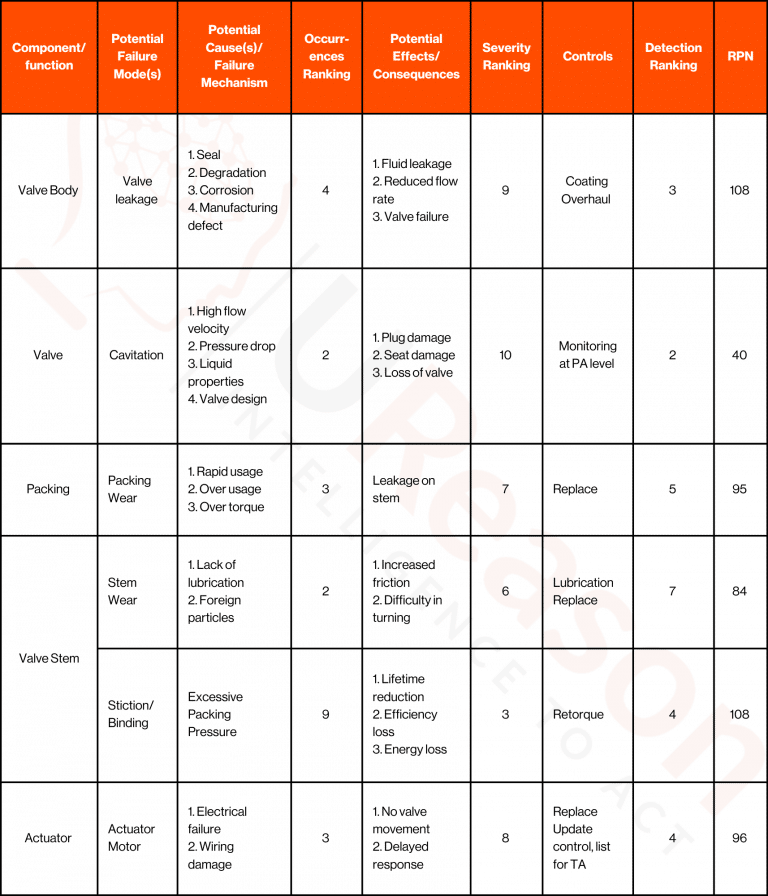

Bringing everything together here is a simplified, reduced example of an FMEA of a Globe Valve with electric actuator:

Please note that the simplified Globe Valve FMEA above excludes the recommended actions as these are often company and situation-specific.