This article is part of a series published by UReason about failure modes and effect analysis of essential components that are common in various industrial processes such as control valves, pneumatic actuators, electrical actuators, motors, and centrifugal pumps.

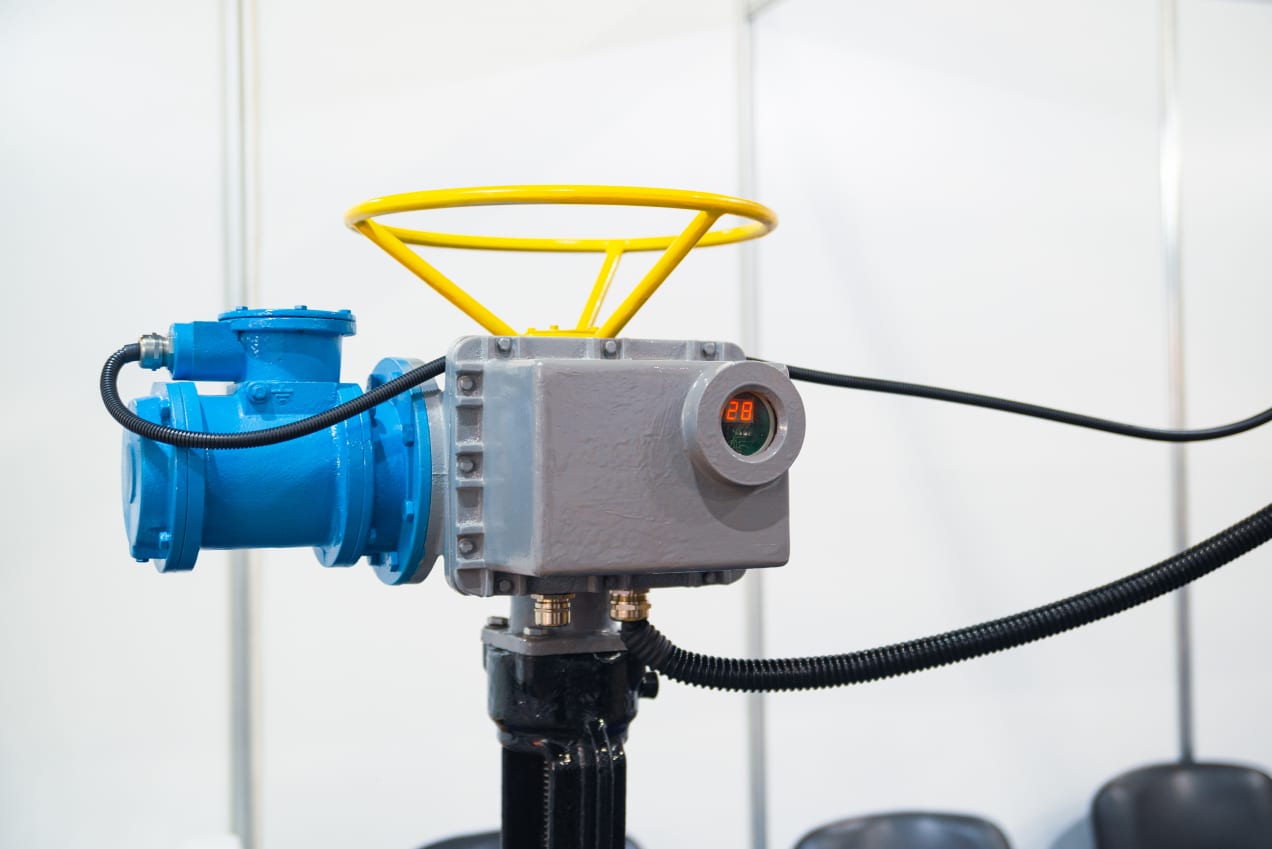

Electric actuators are used in various industrial applications to control the position or movement of valves, dampers, and other mechanical components. Like any mechanical or electrical device, electric actuators can experience several failure modes. These failure modes can vary depending on the type and design of the actuator, but here are some common electric actuator failure modes:

1. Electrical Power Supply Issues:

- Power Interruption: Loss of electrical power can cause the actuator to become unresponsive or fail to operate as intended.

- Voltage Fluctuations: Voltage spikes or fluctuations can damage internal components and affect actuator performance.

2. Mechanical Failure:

- Gearbox Failure: Damage or wear in the gearbox can lead to erratic movement or complete actuator failure.

- Bearing Failure: Bearings may wear out over time, leading to increased friction and reduced efficiency.

- Shaft or Coupling Damage: Damage to the actuator’s shaft or coupling can impede movement.

3. Sensor or Feedback Device Failures:

- Potentiometer Failure: Potentiometers are often used for position feedback. If they fail, the actuator may not accurately position the valve or damper.

- Encoder Failure: Encoders provide precise feedback on the actuator’s position. Malfunctioning encoders can result in inaccurate positioning.

4. Electrical Component Failures:

- Control Board Failure: Malfunctions in the control circuitry or printed circuit boards can disrupt communication with the actuator.

- Wiring Issues: Damaged or disconnected wires can interrupt signal transmission and control.

5. Environmental Factors:

- Moisture and Corrosion: Exposure to moisture or corrosive environments can lead to electrical component damage or rusting.

- Extreme Temperatures: Extreme heat or cold can affect the performance of electronic components.

6. Overload or Over-Torque Conditions:

- Applying excessive force or torque to the actuator can damage internal components or cause mechanical failure.

7. Software or Programming Errors:

- Incorrect or faulty programming can lead to erratic or unintended actuator behaviour.

8. Age and Wear:

- Over time, components may wear out or degrade, leading to reduced performance and eventual failure.

9. External Obstructions:

- Physical obstructions or foreign objects can hinder the movement of the actuator, potentially causing damage or motor strain.

10. Control System Failures:

- Malfunctions or failures in the overall control system, including the control software or hardware, can impact the actuator’s operation.

11. Lubrication Issues:

- Inadequate or improper lubrication of moving parts can lead to increased friction and wear.

To mitigate the risk of electric actuator failures, routine maintenance, including inspections, lubrication, and component testing, is essential. Regularly monitoring the actuator’s performance and ensuring a stable electrical power supply can help prevent unexpected failures. Additionally, selecting the right actuator for the application and following manufacturer recommendations for installation and maintenance can improve reliability and longevity.